What’s a turbocharger’s job? In essence, it’s to extend thermal effectivity. An electrical turbocharger does this and extra, which is why I’m an enormous fan.

Thermal effectivity is a measure of how a lot of the potential power of a gasoline is consumed to create energy, versus how a lot of it’s merely producing waste warmth. In pure phrases, an automotive internal-combustion engine isn’t very environment friendly. For instance, Toyota made an enormous deal within the late 2010s when it achieved 40 % thermal effectivity in its Dynamic Power four-cylinder engine. That means it was solely losing 60 % of its potential power.

Welcome to The Rabbit Gap, a bi-weekly column the place Senior Editor Chris Perkins explores his newest obsession with automotive know-how. He speaks to one of the best within the enterprise to know how vehicles work and what the way forward for the car seems like.

By the way, for this reason EVs have an enchantment past zero native emissions. Thermal effectivity doesn’t apply to electrical motors as a result of they’re in a roundabout way powered by a warmth supply. However when it comes to electrical effectivity—the ratio {of electrical} power a motor consumes to its helpful output—an EV’s motor is about 75 to 90 % environment friendly, in accordance with Renault, not less than.

So, briefly, internal-combustion engines, particularly on their very own, aren’t particularly power environment friendly. Electrical motors are very power environment friendly. Turbocharging will help slender that hole. Thoughts you, it’s nonetheless an enormous hole, however any little bit helps, proper?

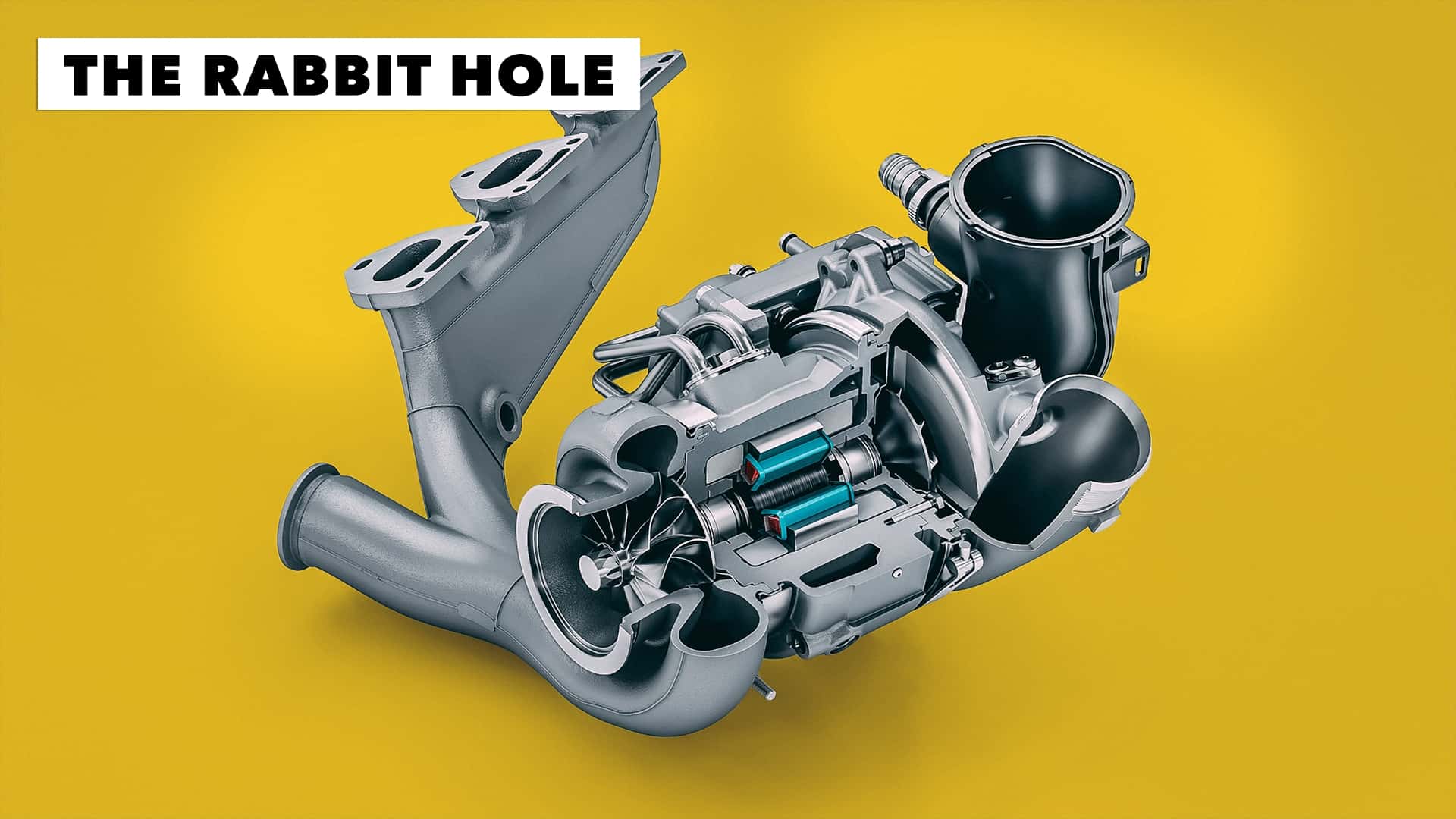

Turbocharging 101: A turbocharger consists of a turbine within the exhaust system, a compressor within the consumption, and a shaft connecting the 2. The exhaust turbine spins up with the circulate of exhaust gases, which in flip spins up the compressor, rising the density of the air headed into the engine, boosting energy. When it comes to thermal effectivity, it takes power that may in any other case be misplaced as warmth and turns it into one thing helpful.

Photograph by: Mercedes-Benz

Turbocharging 201: An electrical turbocharger provides a motor connected to the shaft between the turbine and compressor. This implies you possibly can spin up the turbocharger unbiased of exhaust-gas circulate, which has all kinds of advantages. Most notable is the all-but-elimination of turbo lag, but in addition the decreasing of increase threshold, and permitting for increased increase strain. And easily realizing the shaft velocity of a turbocharger—which admittedly will also be achieved with a easy velocity sensor—permits the automaker to run the turbo extra safely nearer to its most velocity.

However an electrical motor works backward too, producing electrical power in case you use it to brake the turbine. An engineer from Mercedes-AMG as soon as informed me that in some circumstances, an electrical turbocharger might be power impartial; The power the turbocharger’s motor regenerates is sufficient to energy the turbocharger itself.

There are huge thermal effectivity positive aspects available utilizing electrical turbochargers. Mercedes-AMG mentioned in 2017 its electric-turbocharged Formulation 1 V-6 exceeded 50 % thermal effectivity, which was one of many first occasions ever an automotive engine transformed extra of its gasoline supply into helpful energy than waste warmth. Like all F1 engines, the AMG V-6 makes use of a Motor-Generator-Unit-Warmth (MGU-H), which is solely one other time period for an electrical turbocharger. AMG later turned the primary to supply electrical turbochargers in a street automotive with the four-cylinder within the C43 and C63.

Photograph by: Mercedes-Benz

Porsche then took issues a step additional with its hybrid system for the brand new 911 Carrera GTS. Its single BorgWarner turbocharger has a 14.7-horsepower electrical motor on its shaft, and uniquely, no wastegate. Sometimes, a turbocharger makes use of a wastegate—a valve that opens to expel extra exhaust gasoline—to restrict increase strain. Porsche as an alternative brakes the turbocharger’s motor to regulate increase strain, so it isn’t losing any exhaust gasoline and producing extra electrical power. That extra electrical power can energy both the turbocharger itself, or the 53.6-horsepower traction motor sandwiched between the engine and transmission.

Photograph by: Chris Perkins / Motor1

A Porsche engineer additionally tells Motor1 that utilizing a big turbocharger and limiting its turbine velocity with the motor reduces exhaust-gas temperature, and due to this fact, the temperature of the cost air going into the engine. That eliminates the necessity for gasoline enrichment, which is usually used to scale back combustion temperatures, however this apply now being banned with Euro 7 emissions laws. Porsche’s use of an e-turbo boosts the engine’s thermal and gasoline effectivity, and general automobile effectivity.

Broadly talking, going electrical looks like a pure extension for turbocharging. If the purpose of turbocharging is to spice up effectivity, why not go for an answer that furthers that intention? Nicely, electrical turbochargers are costly, difficult, and heavy. Ferrari is utilizing electrical turbochargers for its F80 hypercar, however its closest rival, McLaren, makes use of typical turbos within the coming W1. McLaren engineers informed Motor1 that they didn’t need the additional weight electrical turbos would convey, and that they’d reasonably use the automotive’s electrical power to energy the traction motor.

Including weight and complexity is at all times a tough choice for an automaker, one of many many compromises it should contemplate in the midst of engineering a automotive. The complexity has to justify itself.

McLaren may additionally have some extent on {the electrical} power facet of issues. Up to now, I’ve written about fascinating internal-combustion engine applied sciences, like Mazda’s spark-controlled compression ignition and Nissan’s variable compression.

Each enhance effectivity and efficiency, however not a lot as augmenting inner combustion with a traditional hybrid system. Does electrical turbocharging fall into the identical class? Somebody from one automaker would possibly say sure, however then why would engineering powerhouses like Mercedes, Porsche, and Ferrari all embrace it?

Photograph by: Porsche

Sarcastically, for a know-how that was developed in Formulation 1, the game will quickly abandon electrical turbocharging. To draw extra engine suppliers, F1 is altering its engine formulation for subsequent 12 months to desert the MGU-H, deeming it too costly and never related to street vehicles… simply as extra street vehicles are embracing this know-how.

F1 can also be upping the electrical portion of its hybrid powertrain to realize a few 50/50 break up between engine and motor energy. And hey, F1 is increasing its engine provider base with Audi, Ford, and GM all becoming a member of the fray. F1 is a sport and a enterprise, not merely a technological proving floor.

In any case, turbocharging is, in spirit, about not leaving power on the desk. An internal-combustion engine goes to provide a ton of exhaust gasoline that’s pure waste. Why not make one thing helpful out of that? And why not generate extra electrical power from it whilst you’re at it?

Engineering at its finest maximizes the potential of what you will have in entrance of you. This isn’t to say that vehicles that don’t use electrical turbochargers are dangerous, or that there aren’t respectable causes to skip out on this piece of tech. It’s probably one thing that solely justifies itself in higher-end performance-car purposes. There’s an admirable engineering ultimate with electrical turbochargers that satisfies the nerd in me. Isn’t maximizing potential one thing we should always all try for?

…………………………………………………..

AI IT SOLUTIONS – BLOG4CARS.COM

Subscribe Us.